top of page

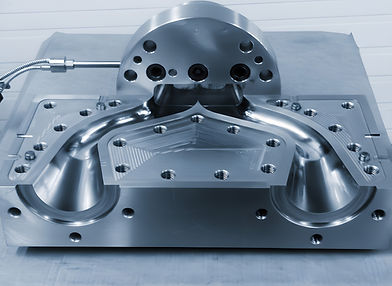

Custom Extrusion Tooling

built for precision, performance, and profitability

Royal CNC is a leading extrusion tooling manufacturer in North America, specializing in custom extrusion tooling design and manufacturing for complex single- and multi-material profiles. With over 35 years of experience, we deliver tooling solutions that improve output quality, reduce lead times, and extend tool life—backed by complete in-house production.

ABOUT US

At Royal CNC Tech, we are dedicated to providing custom extrusion tooling solutions to manufacturers across North America. With over three decades of experience, we specialize in creating parts for extrusion moulding, offering true customization and full vertical integration. Our commitment to excellence extends to our customer service, where we strive to provide expert advice, timely support, and a seamless experience.

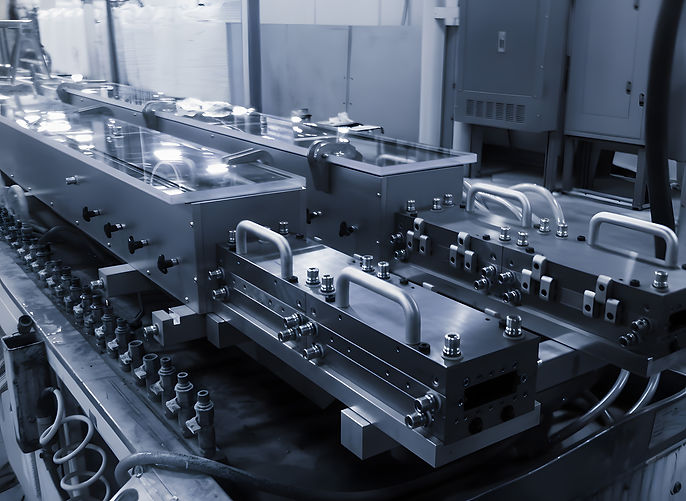

OUR SERVICES

Discover our comprehensive services tailored to meet your custom extrusion tooling needs and enhance your manufacturing processes. From custom parts for extrusion moulding to full vertical integration, we offer a complete range of solutions to optimize production and ensure exceptional quality.

Design & Manufacturing

Precision Engineering

We design and build custom extrusion dies and tooling for single, co-extrusion, and multi-material applications. Each tool is engineered to meet your profile accuracy, production efficiency, and budget requirements.

Tool Maintenance & Servicing

Streamlined Processes

Extend the life of your tooling with our expert maintenance services. We work on both Royal CNC and competitor-built tools, ensuring optimal performance and reduced downtime.

Tool Refurbishment

Broad Knowledge

We restore worn or damaged tooling to like-new condition—improving production consistency while reducing the need for costly replacements.

bottom of page